| No: | Item | Model and specifications |

| 1 | Vehicle brand | aerial operating vehicle |

| 2 | Product number | 5040JGKJ5 |

| 3 | Chassis model | JX1041TG25 |

| 4 | Working height | 14 meters |

| 5 | Main technical parameters of operation | The height of the platform from the ground≥12.3m |

| Maximum operating range of the platform ≥ 8m | ||

| Operating range at the maximum operating height of the platform≥2m | ||

| Operating height at the maximum operating range of the platform≥9m | ||

| Maximum working inclination angle of platform≥75° | ||

| The working arm can be fully extended when working horizontally Rated load of working bucket 200kg | ||

| Outrigger | Mode: Front V and H type, individually adjustable | |

| Quantity: 4 | ||

| Control: Individually adjustable or linked. | ||

| Front leg lateral span: 3622mm | ||

| Inclination: 120° | ||

| Lateral span of rear outrigger: 3700mm | ||

| Hook | Optional hook, maximum lifting tonnage 1000kg | |

| Main operation | Operating position: turntable, remote control operation. | |

| Control form: ZYK bus control system, electric-hydraulic proportional control system to realize continuously variable | ||

| 6 | Hoarding and platform board | Stainless steel fence and anti-skid platform |

| 7 | Boom structure | Three-section -hexagon (14m) type working arm, synchronized telescopic |

| 8 | Slewing device | 360° continuous rotation in both directions, 360° rotation of the hanging basket |

| 9 | Vehicle size | 5998×2000×2900 |

| 10 | Total mass | 4495kg |

| 11 | Curb quality | 4365kg |

| 12 | Wheelbase | 3360mm |

| 13 | Chassis configurations | kv100 single-row cab, model QL1043BUHAY 130-horsepower diesel engine, with direction assist, 3360 wheelbase, 7.00R16 steel wire tires, five-speed gearbox, oil brake, air conditioning, and other national standards Preparation. |

| 14 | Upper assembly system: | The working height is 14 meters aerial operating vehicle adopts a telescopic straight arm structure, the operating arm is a 3-section telescopic type. The color of the upper part is engineering yellow according to the announcement. The whole vehicle has four hydraulic telescopic legs (up and down telescopic and horizontal telescopic), a total of eight cylinders, the legs are front V and rear H type, emergency pump, bucket belt 360 Degree rotation, wireless remote control, others are prepared according to factory standards. |

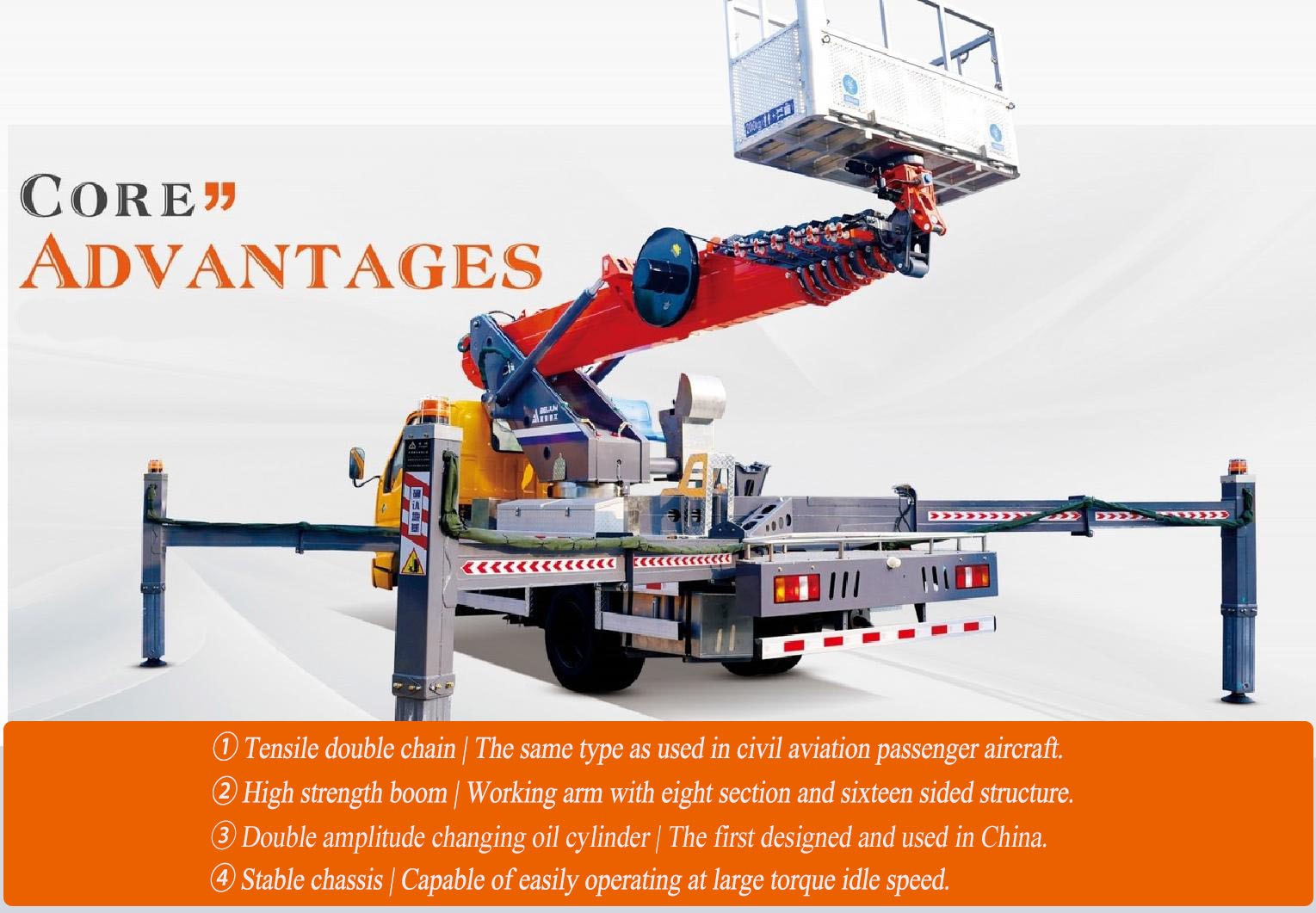

Excellent manufacturing process

① Whole vehicle powder spraying process

Through processes such as shot blasting, electrostatic spraying, high – temperature curing, and cooling, a hard coating film is formed on the vehicle body, with higher wear – resistance and anti – corrosion properties.

② High standard welding process

The boom adopts three dimensional flexible welding technology, with dense welding seams, beautiful formation, and no slag on the surface.

At the same time, the double – sided boring, milling, and planning process is used to improve the smoothness and integrity of the boom, and the high – precision processing and installation are seamless.

③ Assembly process

The torque of all bolts is measured by torque wrenches, effectively improving the reliability of component connections and enhancing anti – loosening ability.

Perfect safety devices

① Automatic interlocking device for getting off:

Prevent danger caused by incorrect operation.

② Second level safety early warning device:

When the vehicle has a virtual leg, the system will automatically issue a safety hazard alarm.

③ Horizontal detection function:

Detect the horizontal state of the entire vehicle in real time to ensure that the vehicle is always level.

④ Emergency braking system:

In case of sudden accidents, operations can be stopped urgently, improving operation safety in complex environments.

⑤ Manual emergency pump:

When the main pump of the main engine fails, the manual emergency pump will be activated to safely send the workers to the ground and retract the entire vehicle to the driving state.

⑥ Nighttime safety warning devices:

Each outrigger is equipped with an engineering strobe light to constantly remind passersby to keep away. In addition, it is also equipped with lighting lamps to facilitate operations at night.